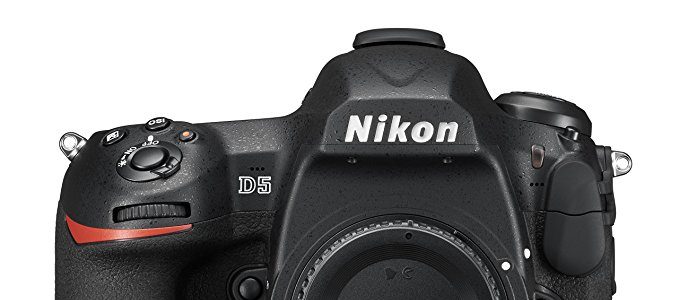

Did You Know Nikon Designs its own Sensors?

I didn’t.

Imaging Resource’s Dave Etchells had the rare chance to visit Nikon’s super-secret sensor design laboratory. But, wait, didn’t Sony manufacture the sensors in Nikon cameras?

So what is Nikon exactly doing? Say’s Etchells:

Companies designing chips of whatever sort generally rely on standard processes established by the “foundry” company that does the actual manufacturing. In these cases, the design process is “just” a matter of defining the layout of the devices on the chip. I say “just” though, because it’s far from a routine process to do this. The size and shape of transistors, photodiodes, resistors and capacitors determines their electrical characteristics, and there are loads of tradeoffs involved in balancing light-gathering efficiency, noise levels, readout speeds, on and on. A big trick is designing the pixels and readout circuitry so there’s as little “dead” (non-light-sensitive) area as possible, while maintaining readout speeds and minimizing power consumption.

Nikon designs its sensors and Sony manufactures them. The surprising thing here is how deep into details Nikon’s sensor design goes, let alone all the simulations and the testing. The reason Nikon is doing this, has to do

with being able to optimize the camera system as a whole, in ways that you can’t if you’re just using off-the shelf parts

In other words: Nikon wants their sensors to be optimised for their lenses and to work at best with Nikon’s also in-house designed EXPEED image processing engine. The sensors featured in the Nikon D850 and Nikon D5 are an example of Nikon’s testing, simulation and overall sensor design.

To learn more about imaging sensors in general and about Nikon’s super-secret sensor design laboratory head over to Imaging Resource.