The Canon 35MMFHDXS CMOS sensor is a high sensitivity and low-noise champion

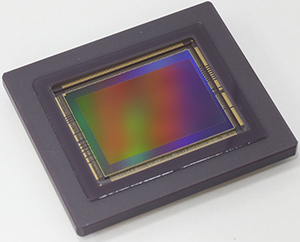

Here is another sensor prototype from Canon. The Canon 35MMFHDXS CMOS sensor was recently presented along with other prototypes The sensors are a 120 Megapixel CMOS Sensor, a 5 Megapixel Global Shutter CMOS, and the 35MMFHDXS, 19μm Full HD CMOS Sensor. If you’re curious to learn more click here.

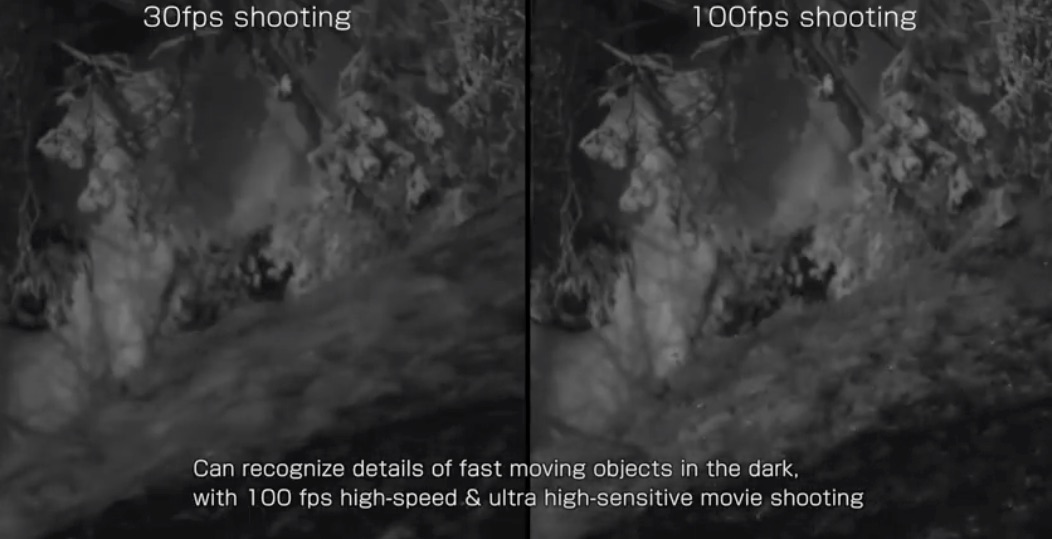

The 35MMFHDXS CMOS sensor delivers high-sensitivity, low-noise imaging performance, enabling the capture of Full HD video even in exceptionally low-light environments. The sensor’s pixels and readout circuitry employ new technologies that reduce noise, which tends to increase as pixel size increases. High sensitivity and increased well depth have been achieved through a larger pixel size of 19μm x 19μm (square) with proprietary device design technologies. The 35MMFHDXS CMOS sensor is available in RGB, RGB+IR or Monochrome.

The 35MMFHDXS CMOS sensor is featured on the Canon ME20F-SH, a specialised, multipurpose camera system. If you are technically inclined you may want to have a look at this Canon White Paper, talking about the 35MMFHDXS CMOS sensor.

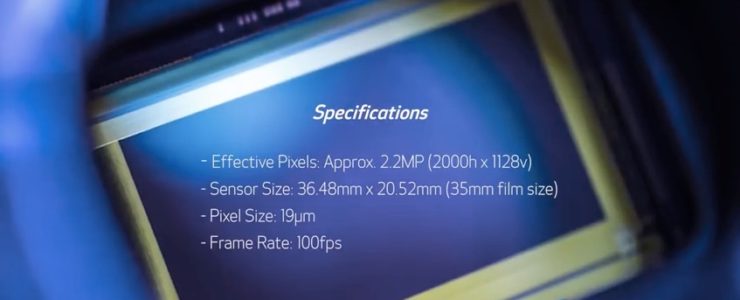

The sensor specifications:

- Sensor size: 35mm film size (36.48mm x 20.52mm)

- Number of effective pixels: 2000h x 1128v, Approx. 2.2MP

- Filter types:

- 35MMFHDXSC: RGB

- 35MMFHDXSM: Monochrome

- Pixel size: 19μm x 19μm

- Progressive scan

- Rolling shutter

- Serial communication

- 180pin ceramic PGA

- Sensitivity:

- 35MMFHDXSC (Green): 1,100,000e/lx/sec @gain x1

- 35MMFHDXSM: 2,100,000e/lx/sec @gain x1

- Saturation: 61,000e @gain x1

- Dark RN: 2.2e rms @gain x16, around 35 °C

- Dark Current: 250e/sec @gain x16, 60°C

- Simultaneous reading of vertical 4 lines

- Drive frequency: 16ch x 18MHz (Recommended)

- Output format: Source follower output (Analog)

- Built in column amplifiers: (Basic pre-amplifier gain: x1, x4, x16)

- Power consumption: 2.2W (At 60 fps under recommended operating conditions)

- Power supply voltage: 5V, 3.3V, others

- Package size: 60.9mm x 44.6mm x 3.57mm

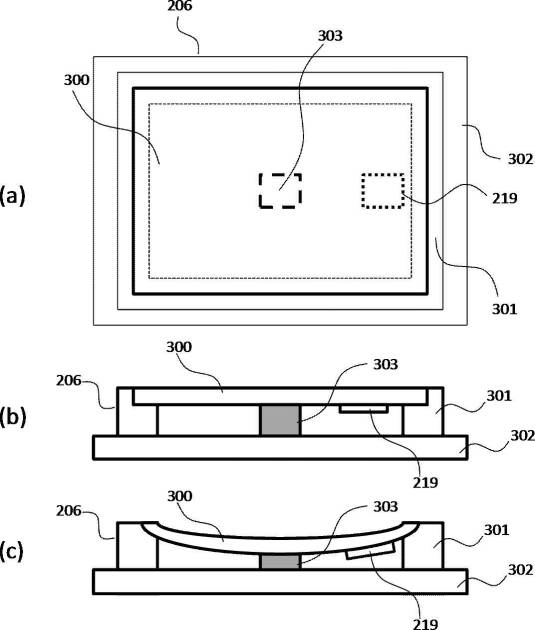

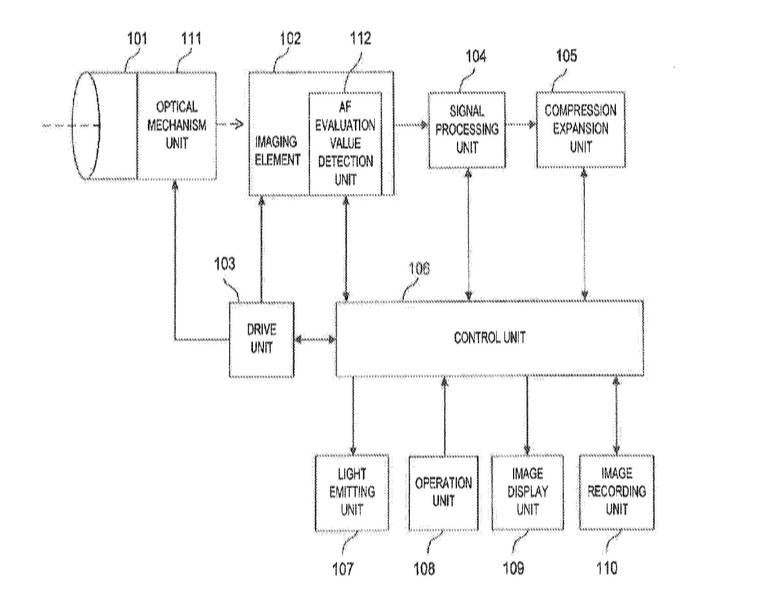

Among the huge amount of patent applications filed by Canon, some show how intensely Canon is researching sensor technology.

Among the huge amount of patent applications filed by Canon, some show how intensely Canon is researching sensor technology. Canon patent application

Canon patent application